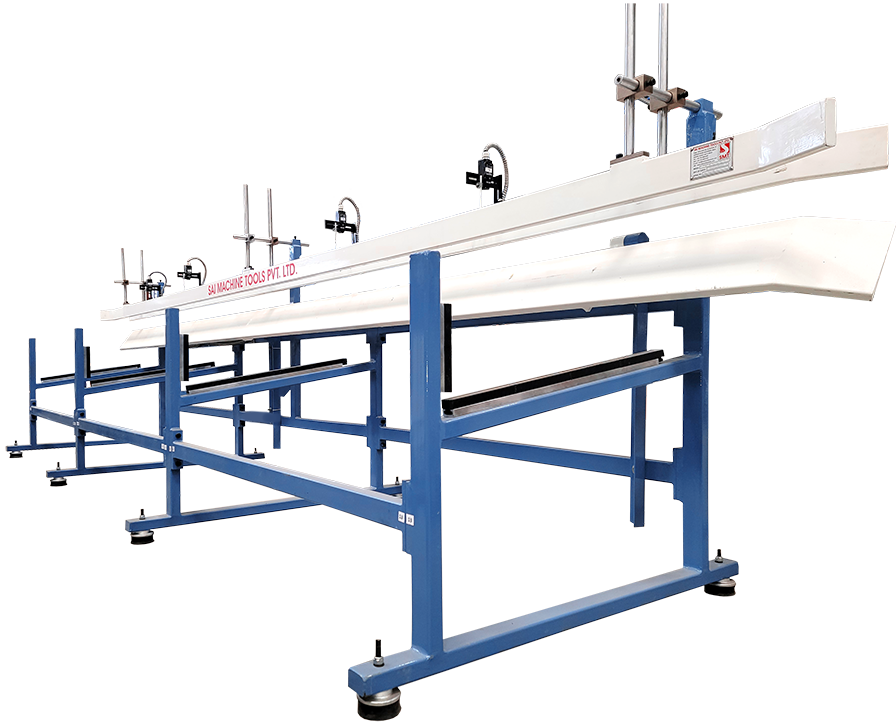

TIP TABLE

FEATURES

- Fully automatic with Pneumatic Operation.

- Metal welded frame.

- Central line adjustment.

- Special roller to avoid pipe surface scratches.

- Synchronized with pipe line speed.

MODEL | PRODUCT CODE | PIPE RANGE (MM) | CUTTING LENGTH | OPERATION |

SMT-KR-50 | PC-24000 | 16 mm to 50 mm | 3 MTR | PNEUMATIC |

SMT-KR-110 | PC-186000 | 20 mm to 110 mm | 6 MTR | PNEUMATIC |

SMT-KR-200 | PC-186000 | 20 mm to 200 mm | 6 MTR | PNEUMATIC |

SMT-KR-250 | PC-94000 | 32 mm to 250 mm | 6 MTR | PNEUMATIC |

SMT-KR-315 | PC-94000 | 63 mm to 315 mm | 6 MTR | PNEUMATIC |

SMT-KR-450 | PC-160000 | 110 mm to 450 mm | 6 MTR | PNEUMATIC |

SMT-KR-500 | PC-160000 | 200 mm to 500 mm | 6 MTR | PNEUMATIC |

SMT-KR-710 | PC-418000 | 450 mm to 710 mm | 6 MTR | PNEUMATIC |

SMT-KR-1200 | PC-597000 | 500 mm to 1200 mm | 6 MTR | PNEUMATIC |

SMT-TKR-110-CD-510 | PC-533000 | 20 mm to 110 mm | 6 MTR | PNEUMATIC |

SMT-TKR-200-CD-770 | PC-665000 | 20 mm to 200 mm | 6 MTR | PNEUMATIC |

FRICTION

WELDING MACHINE

HDPE PIPE FRICTION WELDING MACHINE

Our Heavy Duty MS – Structure, two Station Friction-welding, semi-automatic Machine can weld Head and Tail Part of Sprinkler at the same time accurately using 2 axis friction welding technology.

FEATURES

- Technologically Advanced Machine With

- 2 Axis Friction Welding.

- Semi-automatic Operation With

- Operator Safety.

- Welds All Sprinkler Pipes As Per is 14151 As Per Coupler Design.

- Fitted With Brake Motor For Feed Adjustment And Coupler.

- Rotation With Dynamic Brake.

- Easy Quick Change Fixture For All The Above Sizes.