PVC-O Pipe Extrusion System

Indian's 1st OPVC Pipe Plant with 100% Indigenous Technology

Next-Gen PVC-O Technology for Modern Water Infrastructure

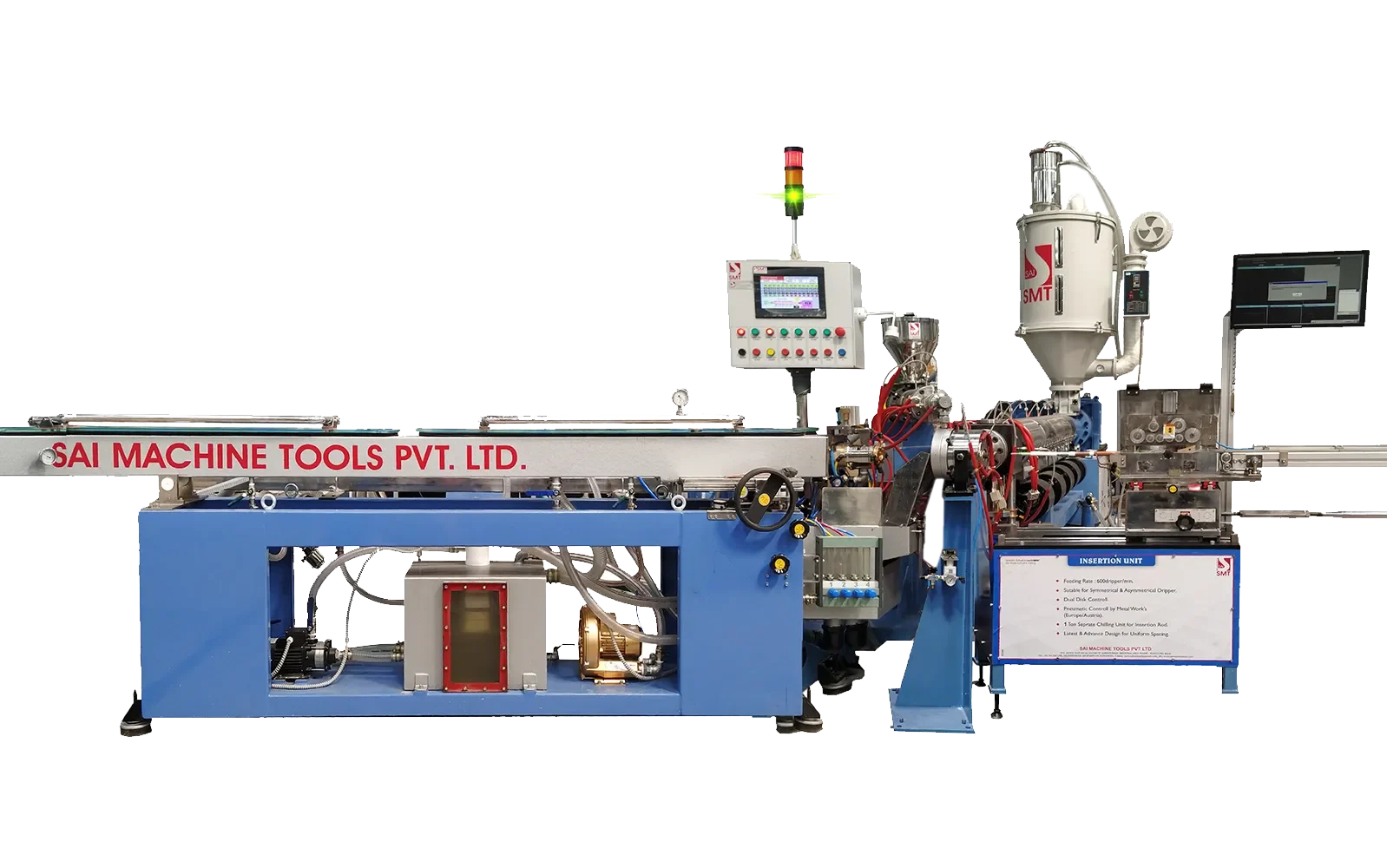

Sai Machine Tools Pvt. Ltd. proudly presents India’s first advanced PVC-O Pipe Extrusion System, developed using state-of-the-art technology for manufacturing bi-axially oriented PVC (PVC-O) pipes. With over 37 years of industry expertise and 3500+ global installations, SMT continues to lead innovation in plastic pipe extrusion technology.

The PVC–O Pipe Extrusion System is specially engineered for producing oriented PVC pipes that combine high strength, superior impact resistance, and lightweight properties, making them the ideal choice for modern infrastructure and industrial applications.

Stronger Pipes. Faster Production. Smarter Technology.

Field Of Application Of PVC- O Pipe

- Advanced Temperature Control

- Low Maintence Design.

- High Automation And Control.

- Conical Twing-Screw Extruder.

- Optimized Screw Design.

- High Output And Energy Efficiency.

PVC-O Machine Specification

Model | Screw Type | Screw Dia (MM) | L:D Ratio | Main Motor (KW) | Max. Output (Kg/Hr.) | Pipe Range (MM) |

SMT-65RPVC-110 | SINGLE SCREW | 65 | 24:1 | 11 | 50 | 16-100 |

SMT-75RPVC-110 | SINGLE SCREW | 75 | 24:1 | 18 | 80 | 16-110 |

SMT-90RPVC-200 | SINGLE SCREW | 90 | 24:1 | 22 | 100 | 50-200 |

Applications of PVC-O Pipes

PVC-O pipes produced on our machine are used in many industries:

1. Potable Water Supply

Ideal for main distribution lines and house connections.

2. Irrigation & Agriculture

Perfect for high-pressure drip and sprinkler systems.

3. Sewage & Drainage

Smooth inner surface reduces blockages and improves flow.

4. Industrial Piping

Suitable for chemical plants, water treatment, and industrial water transport.

5. Infrastructure Projects

Used in smart city development, water networks, and government projects.

Why Choose Our PVC-O Machine?

37+ years of industry experience

Complete machine setup from extrusion to orientation

High-quality components and durable design

Exported to 35+ countries

Reliable service, global support, and expert installation

Affordable and low-maintenance system

Have A Better Experience

Why choose Sai Machine Tools PVC-O Pipe Extrusion Machine

1. Proven Industry Experience

We have more than 37 years of experience in plastic pipe machinery, giving you trusted technology that works in real production environments.

2. World-Class Build Quality

Our PVC-O machines are built with high-grade components, ensuring long life, stable performance, and smooth machine operation.

3. Advanced Orientation Technology

We use precise axial and radial stretching systems to create strong, lightweight PVC-O pipes with uniform molecular orientation.

4. Easy-to-Operate System

The machine comes with a user-friendly PLC touchscreen panel that helps your team run the line with minimal training.

5. High Efficiency, Low Running Cost

Our system uses less power and material, helping you reduce production cost while increasing output.

6. Custom Machine Configurations

We design PVC-O lines to match your production needs — pipe diameter, output capacity, and automation levels.

7. Reliable Service & Global Support

From installation to training and after-sales service, our technical experts support you throughout the machine’s lifetime.

8. Trusted by Customers Worldwide

With more than 3500+ installations across 35+ countries, Sai Machine Tools is one of the most respected names in pipe machinery.

Round Drip Extruder

Discover our state-of-the-art line of round drip irrigation pipe extrusion machines.

Flat Drip Extruder

nvest in productivity with our innovative flat inline drip machine.

Dripper Sorting Machine

Explore our most advanced drip sorting machine with low power consuption feature.

Die Head

SMT pipe making machine manufacturer present top quality Diehead for best extrusion line.

Cooling Tank

SMT cooling tank and vacuum tank for PE,PVC and PPR pipelines. Order Now!

Punching Unit

Punching unit is works as a main part of a drip machine which makes hole in drip tube with perfect measurement.

PVC Cutter

HDPE, PVC, PE and Irrigation pipe cutters made in India by – SMT

Drip Coiler

ound drip coiler is semi automatic which helps you in wrapping drip tube and make it in bundle.