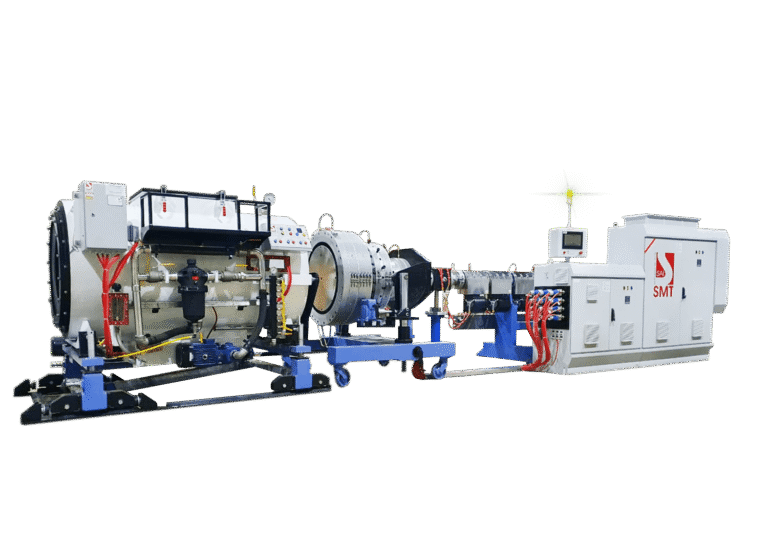

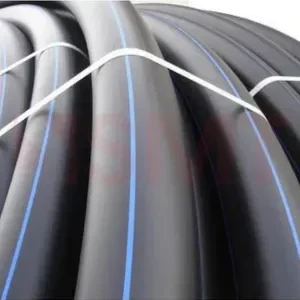

HDPE Pipe Extrusion Machine

HDPE Pipe Production Line Manufacturer

SAI MACHINE TOOLS specializes in providing comprehensive turnkey production lines for all PE material: LLDPE, LDPE, MDPE, HDPE, and pipe manufacturing. Our HDPE pipe machines boast of a wide range of high-capacity main extruders. At SAI MACHINE TOOLS, we also offer complete sets of tooling for various pipe classes, including PN (Pressure Nominal) and SDR (Standard Dimension Ratio), meeting the industry requirements. Our production lines are available in a wide range of configurations, which enable the seamless production of PE pipes ranging from 16 mm to 1200 mm in diameter (with different machine models).

Sai Machine Tools Pvt. Ltd. (SMT)

Our pipe plants which are made of the best possible material facilitate processes to ensure top-notch quality products. Our HDPE multi-layer twin line plant is more than just a production facility. It’s a testament to our commitment to innovation, sustainability and excellence. With our new HDPE multi-layer twin line plant, we’re better equipped than anyone else to meet the needs of our customers.

HDPE Machine Highlights

Main Extruder screw diameter

65mm, 75mm, 90mm and 120mm

Coating extruder screw diameter

45mm, 65mm and 75mm. (for three layer)

Pipe range

16mm to 1200mm

Output capacity

150kg/hr-1200kg/hr. (max.)

A Feature-Packed

Powerhouse for Efficiency and Quality

- Requires low space both lengthwise and width wise (180FeetX15Feet).

16 to 19 tonnes per day production in 63, 75, 90, 110mm dia pipe coil.

Electrical production cost 0.25 to 0.27 units per KG. (Guaranteed).

Low manpower required.

Fully weight controlled and automated plant.

Can use 80% to 90% RP (reprocessing material) guaranteed.

Fully digitally controlled plant to help find labour, electrical and production cost per kilogram.

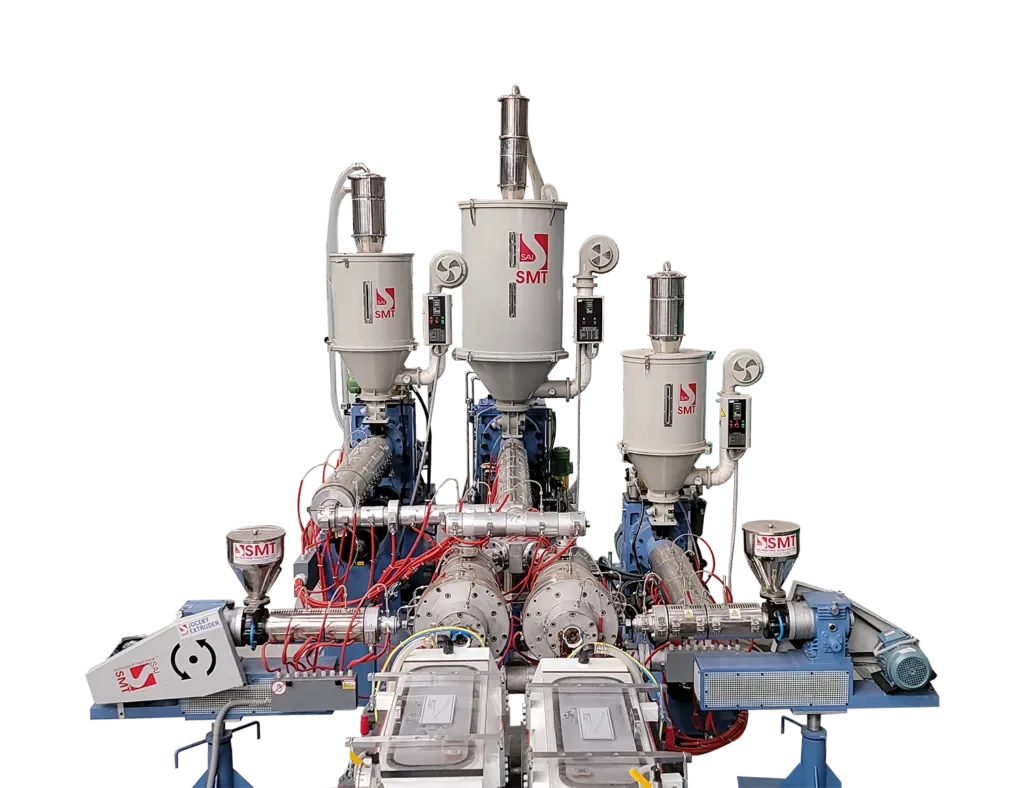

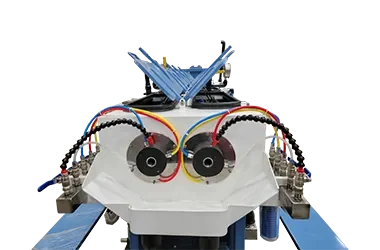

Twin Line HDPE Extruder

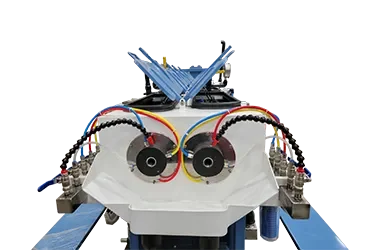

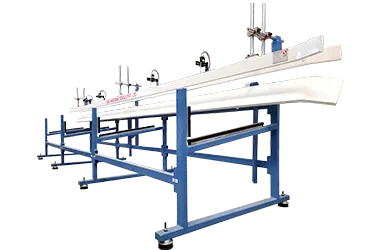

Twin Line Tank

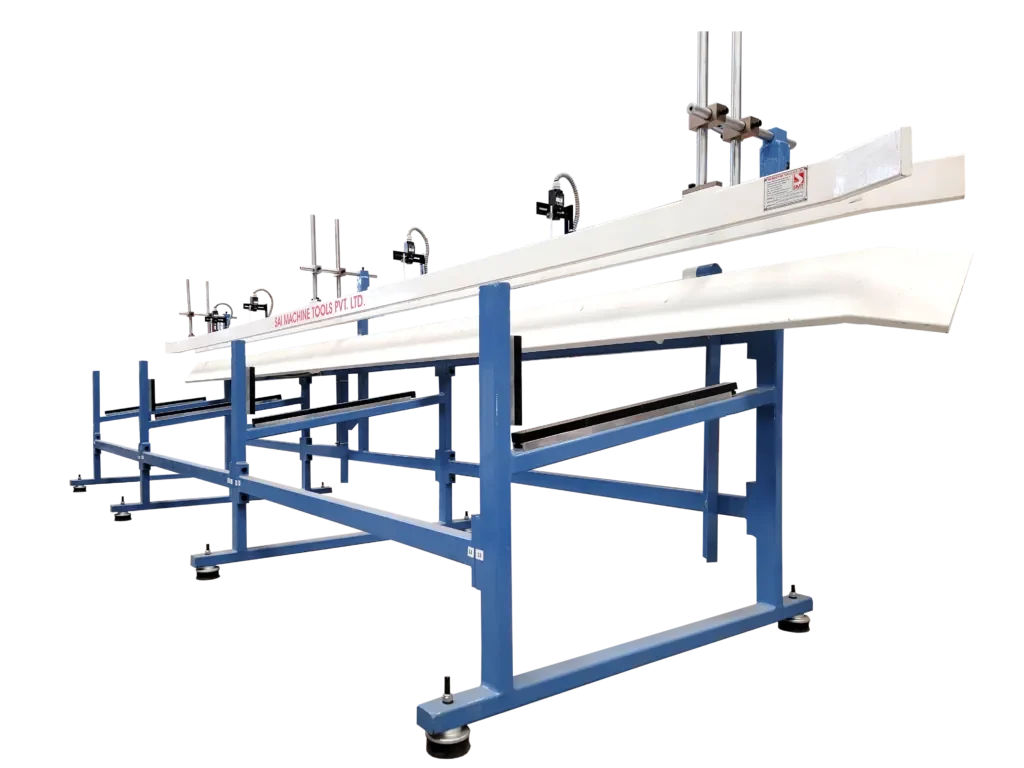

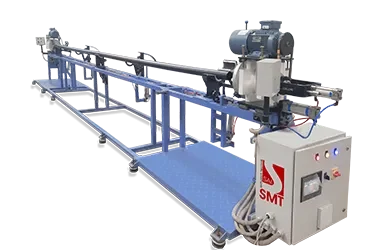

HDPE Tip Table

A Deep Dive into the

Specifications of Sai Machine

Tools' Single Layer HDPE Machine

MODEL | Layer | Screw Dia (MM) | L:D Ratio | Main Motor (KW) | Max. Output (Kg/Hr.) | Pipe Range (MM) |

SMT-65X30-HD-110 | SINGLE LAYER | 65 | 33:01 | 37 | 150 | 16-110 |

SMT-75X30-HD-110 | SINGLE LAYER | 75 | 33:01 | 55, 75 | 200, 300 | 20-110 |

SMT-75X30-HD-200 | SINGLE LAYER | 75 | 33:01 | 55, 75 | 200, 300 | 20-200 |

SMT-75X30-HD-250 | SINGLE LAYER | 75 | 33:01 | 110, 160 | 400, 500 | 63-250 |

SMT-75X30-HD-315 | SINGLE LAYER | 75 | 33:01 | 110, 160 | 400, 500 | 63-315 |

SMT-75X30-HD-450 | SINGLE LAYER | 75 | 33:01 | 110, 160 | 400, 500 | 110-450 |

SMT-75X30-HD-630 | SINGLE LAYER | 75 | 40:01 | 200 | 750 | 250-630 |

SMT-75X30-HD-710 | SINGLE LAYER | 75 | 40:01 | 200 | 750 | 315-710 |

SMT-90X30-HD-200 | SINGLE LAYER | 90 | 33:01 | 110, 160 | 450, 600 | 50-200 |

SMT-90X30-HD-250 | SINGLE LAYER | 90 | 33:01 | 110, 160 | 450, 600 | 63-250 |

SMT-90X30-HD-315 | SINGLE LAYER | 90 | 33:01 | 110, 160 | 450, 600 | 63-315 |

SMT-90X30-HD-450 | SINGLE LAYER | 90 | 33:01 | 110, 160 | 450, 600 | 110-450 |

SMT-90X30-HD-630 | SINGLE LAYER | 90 | 33:01 | 160 | 600 | 250-630 |

SMT-90X30-HD-710 | SINGLE LAYER | 90 | 33:01 | 160 | 600 | 315-710 |

SMT-120X30-HD-1200 | SINGLE LAYER | 120 | 38:01 | 355 | 1200 | 500-1200 |

Note: Aforesaid Machine Models may vary due to customised requirement and continuous R&D.

Mastering the Technical

Blueprint of Sai Machine Tools' Multi-Layer

HDPE PE Pipe Production Line

MODEL | Layer | Screw Dia (MM) | L:D Ratio | Main Motor (KW) | Max. Output (Kg/Hr.) | Pipe Range (MM) |

SMT-65X45X45X30HD-110 | THREE LAYER ABC TYPE | 65+45+45 | 33:1 | 37+7.5+11 | 180 | 16-110 |

SMT-75X45X45X30HD-110 | THREE LAYER ABC TYPE | 75+45+45 | 33:1 | 75+11+15 | 350 | 20-110 |

SMT-75X45X45X30HD-200 | THREE LAYER ABC TYPE | 75+45+45 | 33:1 | 75+11+15 | 350 | 20-200 |

SMT-75X45X45X30HD-250 | THREE LAYER ABC TYPE | 75+45+45 | 33:1 | 75+11+15 | 350 | 63-250 |

SMT-75X45X45X30HD-315 | THREE LAYER ABC TYPE | 75+45+45 | 33:1 | 110+15+18 | 450 | 63-315 |

SMT-75X45X45X30HD-450 | THREE LAYER ABC TYPE | 75+45+45 | 33:1 | 110+15+18 | 450 | 110-450 |

SMT-75X65X65X30HD-250 | THREE LAYER ABC TYPE | 75+45+45 | 33:1 | 110+45+45 | 600 | 63-250 |

SMT-75X65X65X30HD-315 | THREE LAYER ABC TYPE | 75+65+65 | 40:1 | 200+45+45 | 800 | 63-315 |

SMT-75X65X65X30HD-450 | THREE LAYER ABC TYPE | 75+65+65 | 40:1 | 200+45+45 | 800 | 110-450 |

SMT-75X65X65X30HD-560 | THREE LAYER ABC TYPE | 75+65+65 | 40:1 | 200+45+45 | 800 | 250-560 |

SMT-75X65X65X30HD-710 | THREE LAYER ABC TYPE | 75+65+65 | 40:1 | 200+45+45 | 800 | 315-710 |

SMT-90X45X45X30HD-200 | THREE LAYER ABC TYPE | 75+65+65 | 33:1 | 160+15+18 | 600 | 20-200 |

SMT-90X45X45X30HD-315 | THREE LAYER ABC TYPE | 90+45+45 | 33:1 | 160+15+18 | 600 | 63-315 |

SMT-90X45X45X30HD-450 | THREE LAYER ABC TYPE | 90+45+45 | 33:1 | 160+15+18 | 600 | 110-450 |

SMT-90X65X65X30HD-710 | THREE LAYER ABC TYPE | 90+65+65 | 33:1 | 160+45+45 | 800 | 450-710 |

SMT-120X65X65X30HD-1200 | THREE LAYER ABC TYPE | 120+65+65 | 38:1 | 355+45+45 | 1200 | 500-1200 |

Note: Aforesaid Machine Models may vary due to customised requirement and continuous R&D.

HDPE Extruder

Explore the efficiency of our HDPE pipe extrusion machine

Die Head

SMT pipe making machine manufacturer present top quality Diehead for best extrusion line.

Twin Line Vacuum Tank

SMT cooling tank and vacuum tank for PE,PVC and PPR pipelines. Order Now!

Haul off

Haul Offs (Pipe pulling machine) for LDPE, HDPE and PVC pipelines.

HDPE Cutter

HDPE, PVC, PE and Irrigation pipe cuttersmade in India by – SMT

Tip Table

SMT presents you with reliable tip tables for pipe plants for managing pipe extruding process

HDPE Coiler

With our modern automatic coiler for HDPE pipes, discover productivity. Streamline your business processes.

Friction Welding Machine

Discover the easiest way to operate HDPE pipe friction welding machines.

Why choose

Sai Machine Tools HDPE Pipe Extrusion Machine

What Sizes of Pipe Can Your Machines Produce?

Our complete turnkey lines allowing HDPE/PE pipes (16mm-1200mm) have high-capacity extrusion (up to 1200 kg/hr) meeting PN & SDR standards. They have automation features, energy efficient (0.25 units/kg), and capable of handling up to 80-90% recycled material!

Why Use Sai Machine Tools for My Lines Building HDPE Pipe?

Whether you need small-diameter pipes (16mm) for plumbing applications or large-diameter pipes (1200mm) for municipal applications, our HDPE pipe extruders will produce any pipe size, single-layer to multi-layer.

Are Your HDPE Pipe Machines Energy Efficient?

Yes! Our lines consume only 0.25-0.27 units/kg for a decrease for operational costs by 30% to a conventional system.

Do You Provide Multi-Layer HDPE Pipe Extrusion Lines?

Yes! Our twin/multi-layer lines ensure superior pipe strength for gas or water distribution services (e.g. ABC-type 3 layer) having screw sizes of 120mm+65mm+65mm.

Can The Machines Use Recycled HDPE Material?

Yes! Our systems can support at most 80-90% reprocessed material with no loss of quality to affordably provide a more sustainable product.

What Is The Output Capacity of The HDPE Pipe Machines?

150 kg/hr to 1200 kg/hr. For small workshops to large factories producing HDPE pipe you can produce between 16 tons to 19 tons/day!

How Automated Are Your HDPE Pipe Production Lines?

100% automated! Digital controls, weight control, little manpower, so we can deliver the consistent quality you are looking for and lower labor costs.

Why Is Your HDPE Plant Space Efficient?

Productive space is often limited. Our compact design (180’x15′ footprint) is optimized for production efficiency. It is ideal for high-density urban sites where you may become “space challenged”.

Do You Offer Customized HDPE Pipe Extrusion Solutions?

Yes! We custom screw diameter, output speed, dimensions (e.g., SMT-120X30-Hd-1200), and other factors depending on your needs.

What After-Sales Support Do You Provide?

As a manufacturer based in India, we provide 24/7 technical support, hang on-site training, and prompt spare parts delivery to minimize your downtime.

Are Your Machines and Lines Capable of Producing Very High Pressure Pipe?

Yes! We design and build our lines to create PN rated pipe for high-pressure applications (e.g., water supply, gas pipelines) and have excellent precision thickness control.

How Do Your HDPE Machines Reduce the Cost of Production?

Low energy consumption, Use a high percentage of recycled material, Require very little manpower, Low maintenance costs.

What Makes Your Twin-Line HDPE Extruders Unique?

They combine high output (800 kg/hr), multi-layer flexibility, and precision cooling tanks for faster, uniform production.

Can Your Machines Produce Coiled HDPE Pipes?

Yes! Our systems efficiently manufacture coiled pipes (63mm–110mm) for irrigation and plumbing, with 19 tons/day capacity.

Why Trust Sai Machine Tools as Your HDPE Machine Partner?

Experience The Work Of Art

Our Precious Costumers