Suction Hose

Pipe Extrusion Machine

SAI MACHINE TOOLS

Simplify Your Production with SMT Suction Hose Pipe Extrusion Line

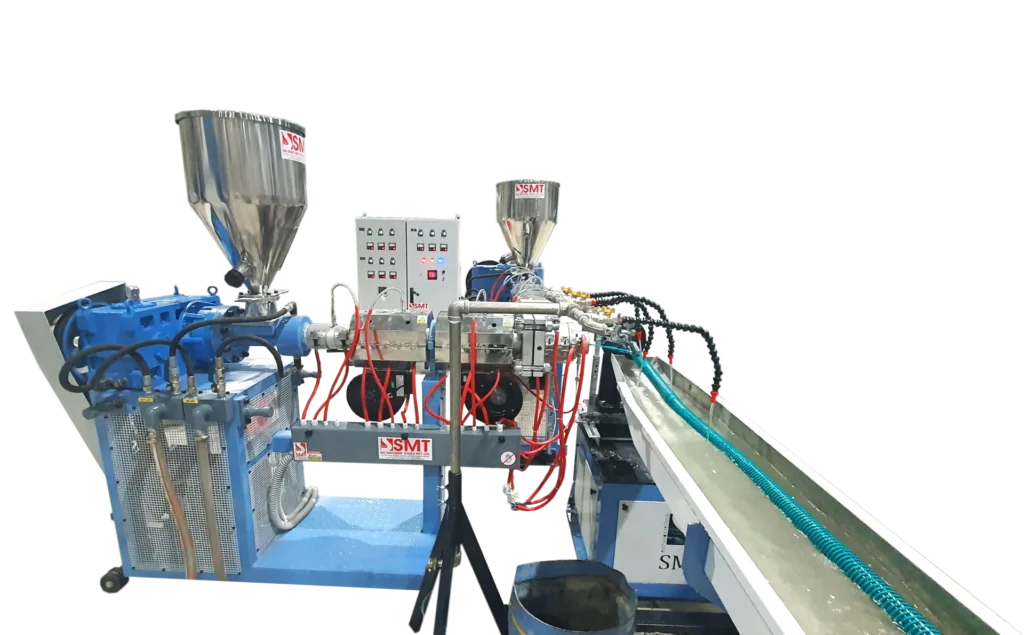

Sai Machine Tools Pvt. Ltd. (SMT) offers state-of-the-art Single Screw Suction Hose Pipe Extrusion Machines designed to deliver precision, performance, and reliability. Our extrusion line is engineered for high-speed production of suction hose pipes ranging from 12mm to 250mm in diameter with an impressive output capacity of up to 160 kg/hr.SMT Single Screw Extruders are offered for extrusion of Suction Hose Pipe Production Line. Suction hose pipe production line consists of 2 extruders, die head, cooling water tank, high speed mixer etc.

Designed with specially designed screw and die head, inverter-controlled AC motor, top brands electrical control units, the whole production line is stable in performance, excellent in quality. The production line has a processing scope of 12 – 250 mm diameter and offers up 160kg/hr in production. Suction hose pipe is mainly used for water supply in agriculture & irrigation and conveyance and delivery of waste, slurry, sludge, industrial and domestic water, chemical & gas supply, pneumatic system etc.

Mastering the Art of Suction Hose Pipe Manufacturing

Manufacturer of High-Performance Suction Hose Pipe Extrusion Systems

At Sai Machine Tools, innovation meets precision engineering. Our Suction Hose Pipe Extrusion Machines are not just production systems—they are a symbol of engineering excellence, sustainability, and long-term value.

Crafted using in-house manufactured components, our extrusion systems ensure operational stability, energy efficiency, and user-friendly automation. Designed to provide maximum satisfaction to our clients, the SMT Suction Hose Line stands as a benchmark for quality, consistency, and productivity.

With our commitment to continuous innovation, we help manufacturers achieve higher output, lower downtime, and superior hose performance—making SMT your trusted partner in extrusion excellence.

Key Features & Advantages

The complete system includes two extruders, a specially designed die head, cooling water tank, high-speed mixer, and intelligent control systems — ensuring maximum operational stability and consistent product quality.

Built with inverter-controlled AC motors, precision screws, and premium electrical components from top global brands, this extrusion line ensures energy efficiency, durability, and optimum output.

Suction hose pipes manufactured on our machines are widely used for:

Agricultural and irrigation water supply

Conveyance of waste, slurry, and sludge

Chemical and gas transfer

Industrial and pneumatic systems

SMT Suction Hose Pipe Extrusion System Must Use For High - Speed Production

Model | Screw Dia (MM) | Motor (KW) | Max. Output (Kg/Hr.) | Pipe Range (MM) |

SMT-50X50 Sch | 50X50 | 7.5+7.5 | 50 | 1/2"to2x1/2" |

SMT-50X65 Sch | 50X65 | 7.5+11 | 60 | 1" to 4" |

SMT-65X65 Sch | 65X65 | 11+11 | 80 | 1" to 6" |

SMT-65X75 Sch | 65X75 | 11+15 | 95 | 2" to 8" |

SMT-75X75 Sch | 75X75 | 15+15 | 120 | 2" to 8" |

SMT-75X90 Sch | 75X90 | 15+22 | 160 | 3" to 10" |

Why Choose Sai Machine Tools for Suction Hose Pipe Extrusion?

Unmatched Quality. Proven Performance. Global Trust.

Sai Machine Tools has earned global recognition for delivering advanced extrusion systems that are built for reliability, versatility, and efficiency. Here’s why industries choose us:

1. Advanced Technology & Performance

Our twin-extruder configuration delivers high output and exceptional hose performance. Machines are available for outputs from 50 kg/hr to 160 kg/hr, adaptable to various hose sizes and formulations.

2. Wide Production Range

Produce suction hoses from ½” to 10” (12mm–250mm) in diameter, suitable for diverse applications in:

Agriculture & irrigation

Waste management

Chemical & industrial fluid transfer

Pneumatic & municipal systems

3. Energy-Efficient Design

Our custom screw design and inverter-controlled AC motors optimize power usage while maintaining stable performance — lowering production costs without compromising quality.

4. Intelligent Automation

The fully automated system ensures consistent production with real-time monitoring, smart control, and automatic coiling—reducing operator dependency and improving safety.

5. Durability & Safety

Each system includes overload protection, emergency stop, and temperature control systems to ensure safe, long-term operation even in demanding environments.

6. Customization & Material Flexibility

Our extrusion lines can process various thermoplastics and rubber compounds, with custom-built options for specific hose diameters and applications.

7. Low Maintenance Design

Heavy-duty construction and high-quality components ensure minimal maintenance — just regular cleaning and lubrication for uninterrupted operation.

8. Global After-Sales Support

We provide installation assistance, operator training, and ongoing technical support to keep your production running efficiently worldwide.

9. Proven Expertise & Trust

With 37+ years of experience, 3200+ installations worldwide, and a commitment to continuous innovation, SMT is one of the most trusted names in plastic processing machinery.

Applications

Agriculture and irrigation

Slurry and sludge transportation

Chemical and gas transfer

Industrial and municipal utilities

Pneumatic and vacuum systems

Partner with the Experts in Hose Extrusion Technology

Whether you’re upgrading your existing production or setting up a new line, Sai Machine Tools provides a complete extrusion solution—from design and manufacturing to installation and support.

Contact us today to learn how SMT’s Suction Hose Pipe Extrusion Line can elevate your production performance and profitability.