Round Drip

Pipe Extrusion Machine

Advanced Technology

Unlocking High-Speed Production, Price-Competitive Value

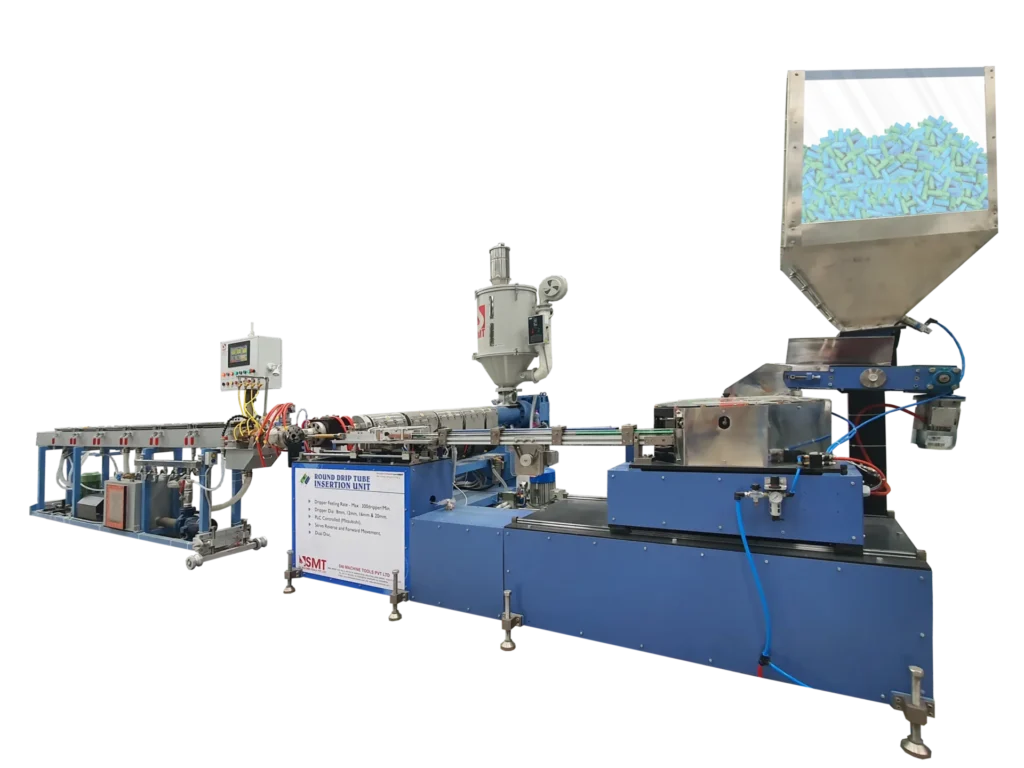

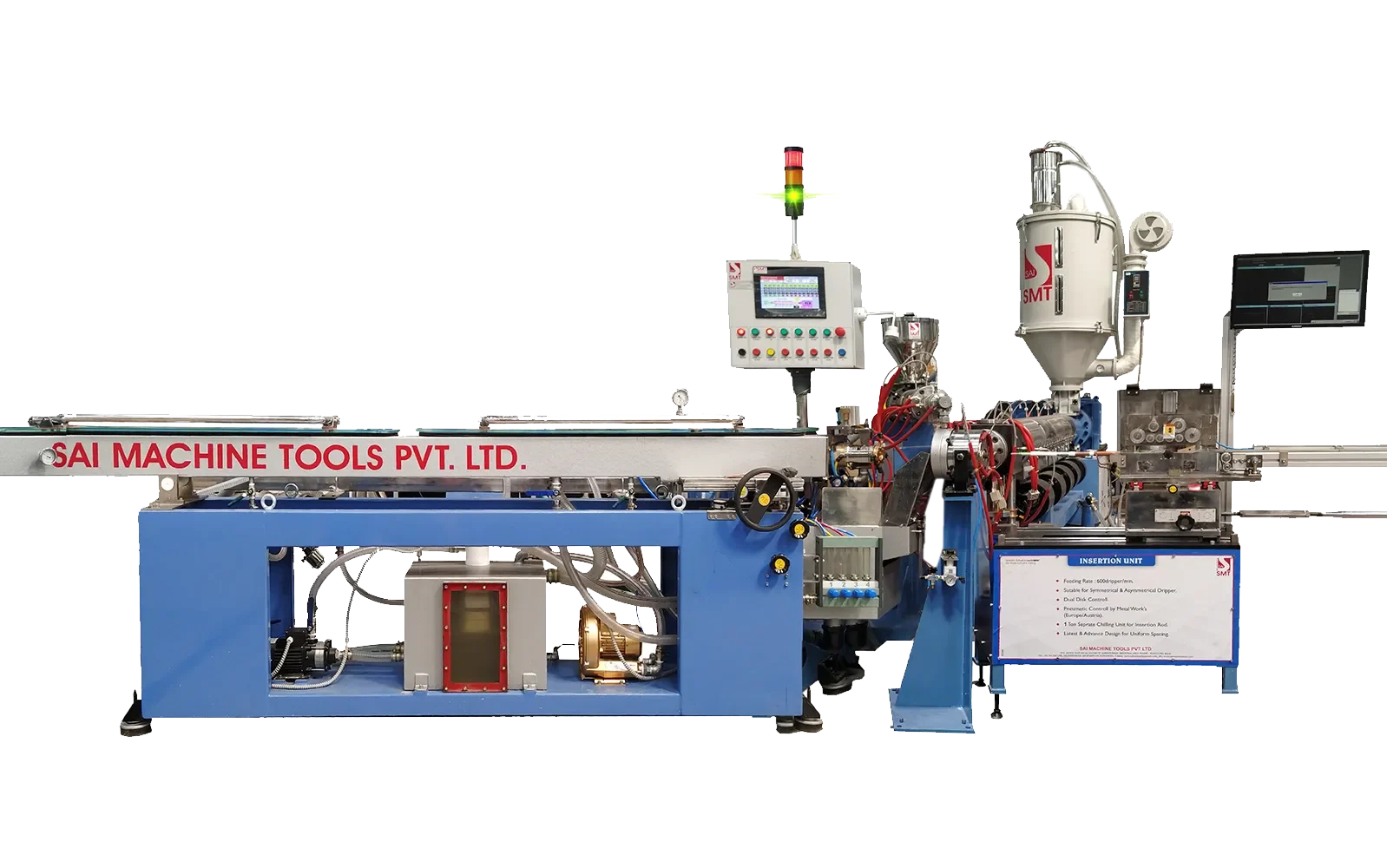

Introducing the state-of-the-art Round Drip Tube Extrusion line by Sai Machine Tools,a precursor to innovation to India’s manufacturing landscape. This advanced plant boasts of cutting-edge features and a sophisticated PLC control system, setting it apart as the pinnacle of technological innovation. With a focus on automation, our Round Drip Pipe Plant offers a comprehensive range of fully automated functions, ensuring maximum efficiency and convenience.

The Round Drip Pipe Plant has been meticulously crafted as a high-speed production line, setting new benchmarks in productivity. With an impressive capacity to insert and perforate up to 500 drippers per minute, this plant ensures optimal performance and seamless operation. Imagine the possibilities of achieving more in less time.

Optimal Performance

And Seamless Operation.

SMT Round Drip Machine Features

- Extruder – 75mm.

- Quick Drill Depth Adjustment.

- Operation by Servo Motor.

- Easy Integration with Existing Line.

- Energy Efficient- No Air Jets.

- Maintenance free.

- Single / Multilayer Tube.

Round drip machine specification

Model | Layer | Max. Output (Kgs/Hr) | Dripper Insertion Speed/Min. | Die Head | Perforation Unit | Line Speed (MPM) | Total Connected Load (Kw) | Space LXWXH (Mtrs) |

SMT-75X-RD | SINGLE | 200 | 500 | CROSS HEAD-SINGLE LAYER | 2 or 4 HOLES | 100 | 144 | 40X8X5 |

SMT-75X45-RD | ABA | 220 | 500 | CROSS HEAD-THREE LAYER | 2 or 4 HOLES | 100 | 155 | 40X8X5 |

SMT-75X45X45-RD | ABC | 250 | 500 | CROSS HEAD-THREE LAYER | 2 or 4 HOLES | 100 | 166 | 40X8X5 |

Round Drip Extruder

Discover our state-of-the-art line of round drip irrigation pipe extrusion machines.

Flat Drip Extruder

nvest in productivity with our innovative flat inline drip machine.

Dripper Sorting Machine

Explore our most advanced drip sorting machine with low power consuption feature.

Die Head

SMT pipe making machine manufacturer present top quality Diehead for best extrusion line.

Cooling Tank

SMT cooling tank and vacuum tank for PE,PVC and PPR pipelines. Order Now!

Punching Unit

Punching unit is works as a main part of a drip machine whis makes hole in drip tube with perfect measurement.

PVC Cutter

HDPE, PVC, PE and Irrigation pipe cuttersmade in India by – SMT

Drip Coiler

ound drip coiler is semi automatic which helps you in wrapping drip tube and make it in bundle.

Why choose Sai Machine Tools Round Drip Pipe Extrusion Machine

Why Choose Sai Machine Tools for Round Drip Irrigation Pipe Machines?

Sai Machine Tools is a pioneer in agriculture machinery, offering high-speed drip irrigation pipe manufacturing equipment designed to meet modern farming demands. Our machines combine cutting-edge automation, no-air jet technology, and servo motor-driven systems to deliver energy-efficient, maintenance-free production lines. Whether you are setting up a new irrigation business or expanding an existing facility, our round drip pipe machines provide reliable solutions tailored to your needs.

Key benefits:

High-speed dripper insertion (500 drippers/minute)

Automated PLC control for precision and consistency

Energy savings of up to 20% with advanced technology

Compact design, ideal for small to medium production facilities

Types of Round Drip Pipes You Can Produce

Our round drip pipe extrusion machines are versatile and capable of producing:

Single-layer drip tubes

Multi-layer (ABA/ABC) drip pipes for enhanced durability

2-hole or 4-hole perforation pipes tailored to different crops

These pipes are widely used in agriculture, horticulture, orchards, and large-scale irrigation projects, ensuring optimal water usage and improved crop yields.

Fast, Efficient Round Drip Pipe Production

Our drip irrigation pipe manufacturing machines offer industry-leading speed and output:

500 drippers per minute

100 meters per minute line speed

200–250 kg/hour output capacity

These features make them ideal for high-volume drip irrigation pipe production, enabling you to scale operations without compromising on quality.

Energy-Efficient Drip Pipe Machines

Energy efficiency is critical in agricultural operations. Our machines replace conventional air-jet systems with servo motor technology, resulting in 20% lower energy consumption. This innovation supports sustainable farming and lowers operational costs.

Easy Integration with Existing Production Lines

Our round drip pipe manufacturing equipment is designed for seamless integration with your current production setup. The modular framework allows for zero downtime and faster installation, helping you expand without delays.

Durability and Maintenance-Free Operation

Our multi-layer extrusion technology (ABA/ABC) ensures that pipes withstand harsh environmental conditions, reducing maintenance requirements and extending service life. With precision hole perforation and anti-clog designs, our drip pipes are optimized for long-term use.

Consistent Dripper Perforation for Uniform Irrigation

Achieving uniform water distribution is critical for efficient irrigation. Our machines utilize automated depth adjustment and PLC-controlled perforation, ensuring every dripper hole is identical in size and flow rate. This prevents over-irrigation and promotes healthy plant growth.

Space-Saving Drip Pipe Production Solutions

With a compact footprint of 40m × 8m × 5m, our equipment is perfect for small-to-mid sized facilities. It helps you maximize floor space without compromising production efficiency.

Customizable Dripper Hole Options

Choose between 2-hole or 4-hole perforations to suit the water requirements of various crops, including fruits, row crops, and specialty plants. Our flexible designs support a wide range of agricultural needs.

Comprehensive After-Sales Support

We are committed to keeping your operations running smoothly with:

✅ 24/7 technical support

✅ On-site training for operators

✅ Fast spare parts supply

✅ Preventative maintenance guidance

Our goal is to ensure that your drip irrigation pipe line operates at peak efficiency.

Maintenance-Free Operation Saves Costs

Our maintenance-free drip irrigation machines feature durable components and no-air jet technology, which significantly reduce wear and tear, resulting in 30% lower maintenance costs and longer equipment lifespan.

Use of Recycled Materials

Sustainability is at the core of our designs. Our machines are capable of processing recycled and reprocessed polymers, helping reduce raw material costs while maintaining high-quality pipe production.

Export-Quality Drip Irrigation Pipe Machines

All our machines meet ISO compliance standards and produce BIS-certified pipes, making them suitable for both domestic and international irrigation markets.

Water-Saving Features of Our Round Drip Pipes

Our pipes are engineered to maximize water efficiency:

Optimal hole spacing to prevent over-irrigation

Uniform flow rates (2–4 LPH) for precise watering

Anti-clog perforations for use with sandy or debris-laden water

These features contribute to significant water conservation and better crop health.

Why Trust Sai Machine Tools for Round Drip Irrigation Pipe Machines?

✅ Over 35 years of extrusion expertise

✅ 500+ installations worldwide

✅ Recognized Make in India brand

✅ Complete automation solutions for scalable production

✅ Trusted by farmers, agribusinesses, and irrigation specialists

Choose Sai Machine Tools for proven, efficient, and reliable drip irrigation pipe manufacturing solutions that meet today’s agricultural demands.