Flat Drip Pipe

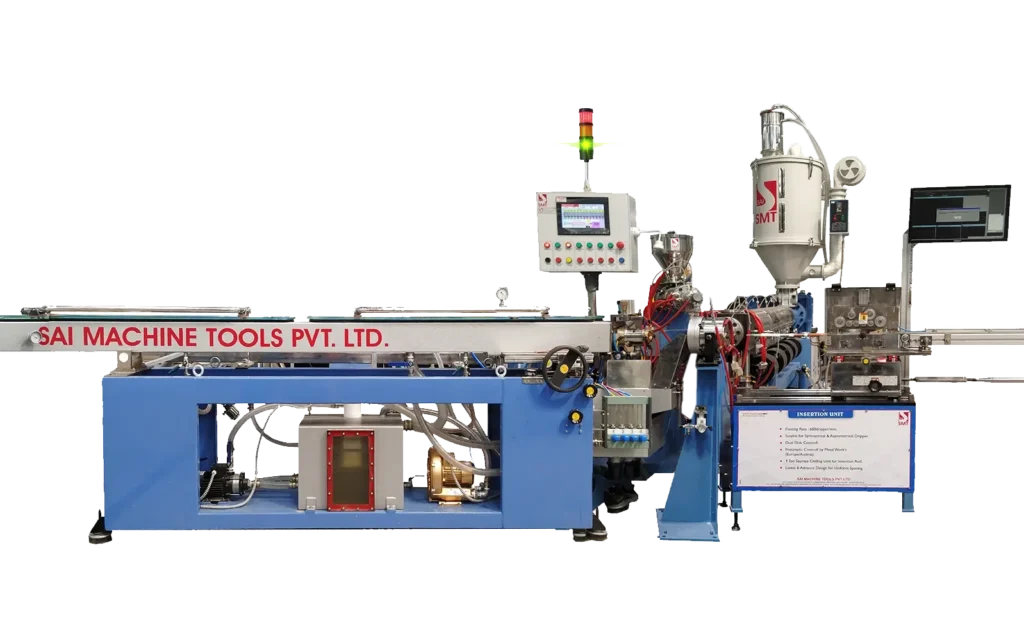

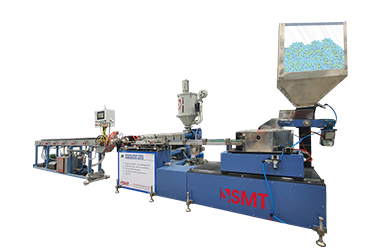

Extrusion Machine

Advanced Technology

Drip Irrigation Pipe Machinery Solutions

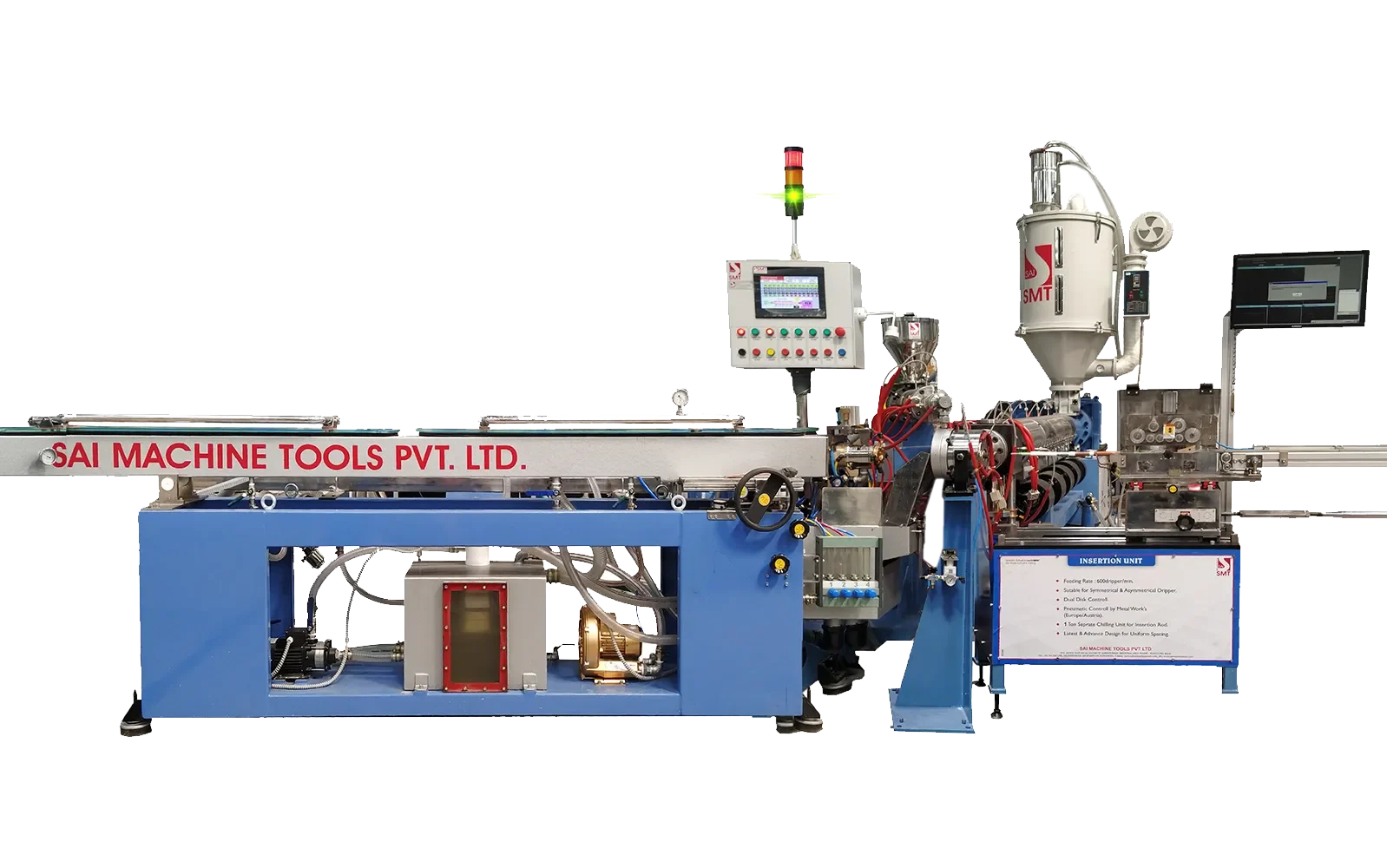

Drip pipe manufacturing machines – that craft precise, water-saving pipes for optimal crop growth. At Sai Machine Tools Pvt. Ltd, we take immense pride in our position as a leading manufacturer of top-tier Drip Irrigation Extrusion Lines. With over 32 years of industry expertise and an unwavering commitment to innovation, we have become the trusted partner for businesses worldwide seeking efficient and reliable solutions for their drip irrigation needs.

Advanced Technology for Enhanced Efficiency Our Drip Irrigation Extrusion Lines are at the forefront of technology, featuring a cutting-edge PLC control system. This advanced system ensures precision and accuracy, resulting in increased efficiency in the production process. It is equipped with fully automated features, guaranteeing enhanced productivity while maintaining minimal power consumption, at just 0.27 units per kilogram of product.

Flat Drip Pipe

Manufacturing Machine

Unveiling

Efficiency at Unmatched Prices

Sai Machine Tools proudly introduces India’s most advanced flat drip tube extrusion system, which is fully based on a PLC control system. This state-of-the-art system is equipped with fully automated features, resulting in enhanced productivity and efficiency, all while consuming minimal power at just 0.27 units per kilogram.

Our flat drip pipe plant is designed to be a top-speed production line capable of inserting and perforating up to 700 drippers per minute. With a remarkable line speed of 220 meters of pipe per minute, it ensures swift and seamless operations. Additionally, the system incorporates an automatic coiler that facilitates efficient coiling of the flat drip tubes.

SMT Flat

Drip Machine Features

- Barrier/ Shear ring Screw Design for Homogeneous melt for longer period.

- PLC Based machine- 500 Drippers/ Min.

- 200- 2000 mm Dripper Spacing.

- Perforation Capacity for Longer Period.

- Single / Multilayer Tube.

- Perforation Unit- 500 Drippers/ Min.

- Perforation Unit with Visual Inspection and Control.

- Auto Coiler with Synchronised Traversing.

- Auto Pipe cut and Changeover.

- Power Consumption- 0.27 Unit/ Kg.

- Line Speed – 220 MPM.

Flat drip machine specification

Model | Layer | Max. Output (Kgs/Hr) | Dripper Insertion Speed/Min. | Die Head | Perforation Unit | Line Speed (MPM) | Total Connected Load (Kw) | Space LXWXH (Mtrs) |

SMT-75X20-FD | SINGLE | 200 | 700 | CROSS HEAD-SINGLE LAYER | 1 or 2 HOLES | 200 | 160 | 45X8X5 |

SMT-75X20-FD-HS | SINGLE | 300 | 700 | CROSS HEAD-SINGLE LAYER | 1 or 2 HOLES | 250 | 200 | 45X8X5 |

SMT-75X45X20-FD | THREE (ABA) | 225 | 700 | CROSS HEAD-THREE LAYER | 1 or 2 HOLES | 200 | 175 | 45X8X5 |

SMT-75X45X20-FD-HS | THREE (ABA) | 300 | 700 | CROSS HEAD-THREE LAYER | 1 or 2 HOLES | 250 | 215 | 45X8X5 |

SMT-75X45X45X20-FD | THREE (ABC) | 250 | 700 | CROSS HEAD-THREE LAYER | 1 or 2 HOLES | 200 | 180 | 45X8X5 |

Round Drip Extruder

Discover our state-of-the-art line of round drip irrigation pipe extrusion machines.

Flat Drip Extruder

nvest in productivity with our innovative flat inline drip machine.

Dripper Sorting Machine

Explore our most advanced drip sorting machine with low power consuption feature.

Die Head

SMT pipe making machine manufacturer present top quality Diehead for best extrusion line.

Cooling Tank

SMT cooling tank and vacuum tank for PE,PVC and PPR pipelines. Order Now!

Punching Unit

Punching unit is works as a main part of a drip machine whis makes hole in drip tube with perfect measurement.

PVC Cutter

HDPE, PVC, PE and Irrigation pipe cuttersmade in India by – SMT

Drip Coiler

ound drip coiler is semi automatic which helps you in wrapping drip tube and make it in bundle.