RPVC PIPE

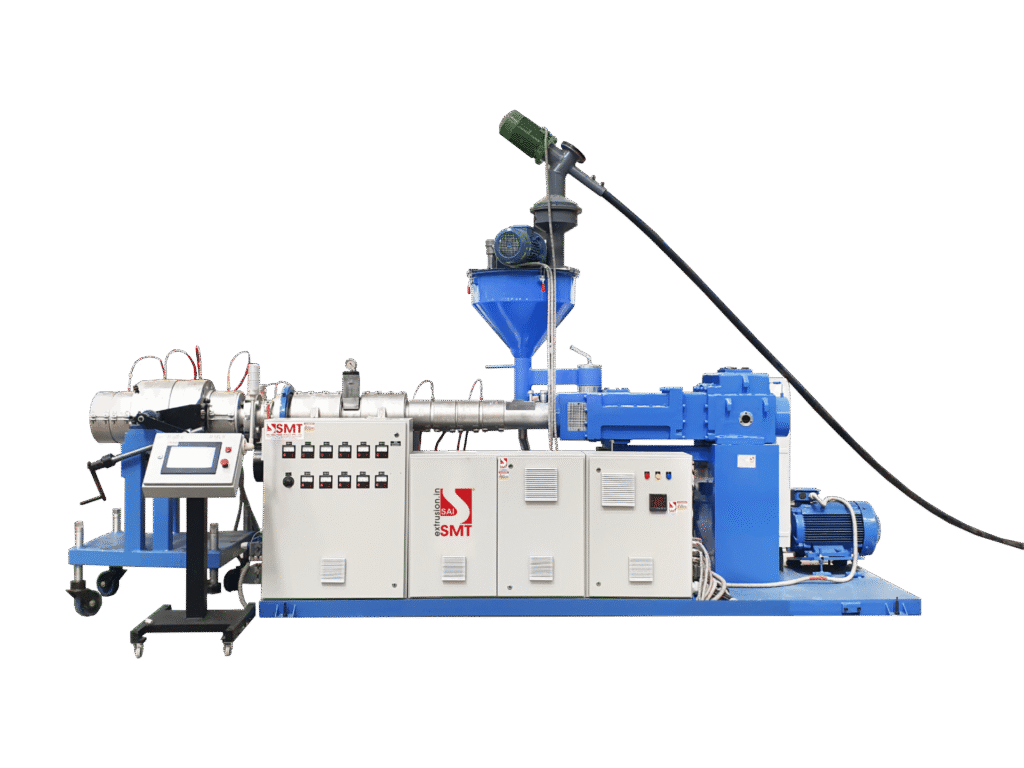

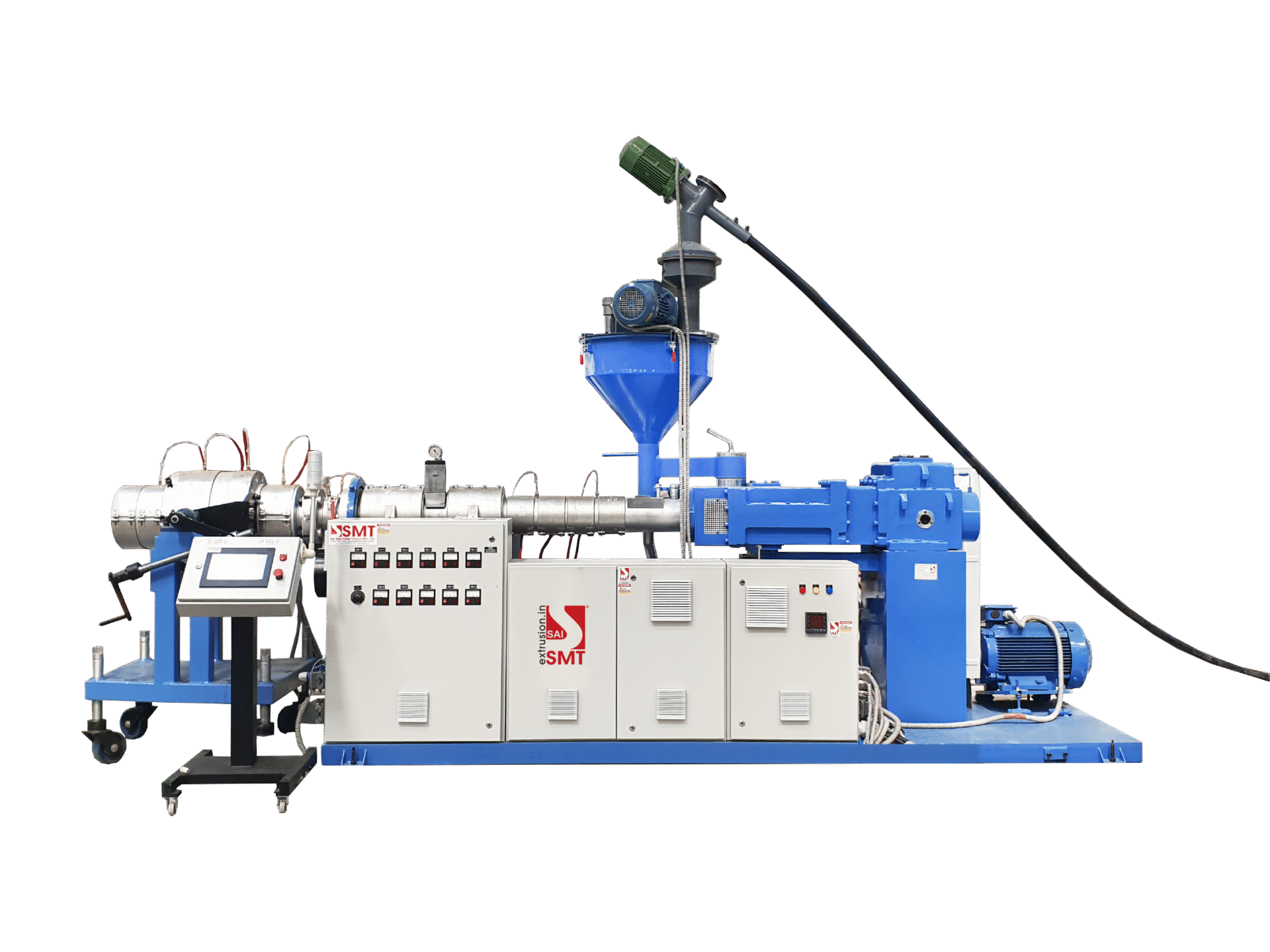

EXTRUSION MACHINE

INTRODUCING NEXT GENERATION

Unmatched Performance with

Twin Screw PVC RPVC Pipe Plants

Specializes in cutting-edge PVC/RPVC Pipe plants, boasting of state-of-the-art Parallel Type Twin screws for optimal raw material blending. Our PVC Pipe Plant is the go-to choice for PVC/RPVC pipes and profiles production, featuring an impressive output range of 110kg/hr to 450kg/hr. With screw diameters ranging from 52mm to 90mm, our PVC/CPVC extruders are known for their high-capacity performance. The parallel extruder design showcases innovation that results in top-tier pipes and a minimal rejection rate. This PLC-controlled pipe extrusion machine offers robust construction for superior performance, ensuring ease of operation. Alleviate your PVC/RPVC pipe production with our advanced machinery solutions.

RPVC twin screw

downline extrusion system

Unveiling the Advantages of Our Twin Screw PVC RPVC Pipe Plants

- Screw Type:

Parallel type - Main Extruder screw dia:

52mm, 65mm, 68mm and 90mm - Pipe range:

20mm to 400mm - Output capacity:

110kg/hr-450kg/hr. (max.)

Key Features of Your RPVC Pipe Production Machine

- Screw Type:

Parallel Type Twin Screws for superior material mixing. - Output Range:

110kg/hr to 450kg/hr, catering to various production needs. - Screw Diameter:

52mm to 90mm, offering versatility in pipe production. - Screw Design:

Innovative parallel extruder design ensures high-quality pipes with low rejection rates. - Control PLC:

Controlled for robust and user-friendly operation. - Application:

Ideal for manufacturing PVC/RPVC pipes and profiles. - Manufacturer:

Sai Machine Tools Pvt Ltd, a trusted name in the industry.

Conical Twin-Screw PVC Machine Specification

MODEL | Screw Type | Down Stream | Screw Dia (MM) | L:D Ratio | Main Motor (KW) | Max. Output (Kg/Hr.) | Pipe Range (MM) |

SMT-52/18V-110 | TWIN SCREW-P | Single | 52 | 18:1 | 11 | 110 | 20-110 |

SMT-52/25V-110 | TWIN SCREW-P | Single | 52 | 25:1 | 18 | 150 | 20-110 |

SMT-65/18V-200 | TWIN SCREW-P | Single | 65 | 18:1 | 18 | 200 | 20-200 |

SMT-65/22V-250 | TWIN SCREW-P | Single | 65 | 22:1 | 30 | 250 | 63-250 |

SMT-90/22V-315 | TWIN SCREW-P | Single | 90 | 22:1 | 55 | 450 | 90-315 |

SMT-65/18V-TDS-50 | TWIN SCREW-P | Dual-CD-200 | 65 | 18:1 | 18 | 200 | 16-50 |

SMT-65/22V-TDS-50 | TWIN SCREW-P | Dual-CD-200 | 65 | 22:1 | 30 | 250 | 16-50 |

SMT-65/22V-TDS-110 | TWIN SCREW-P | Dual-CD-510 | 65 | 22:1 | 30 | 250 | 20-110 |

SMT-90/22V-TDS-125 | TWIN SCREW-P | Dual-CD-510 | 90 | 22:1 | 55 | 450 | 50-125 |

SMT-92/28V-TDS-125 | TWIN SCREW-P | Dual-CD-510 | 92 | 28:1 | 75 | 700 | 63-125 |

SMT-92/28V-TDS-200 | TWIN SCREW-P | Dual-CD-770 | 92 | 28:1 | 75 | 700 | 63-200 |

SMT-92/28V-TDS-125 | TWIN SCREW-P | Dual-CD-510 | 110 | 28:1 | 110 | 900 | 63-125 |

SMT-92/28V-TDS-200 | TWIN SCREW-P | Dual-CD-770 | 110 | 28:1 | 110 | 900 | 63-200 |

RPVC Extruder

Explore top-quality RPVC extrusion machines with the automatic twin-screw technology that is sure to meet all your needs.

Single Screw RPVC Extruder

Unlock precision and efficiency with our state-of-the-art single screw RPVC pipeline making machine.

PVC Socketing Machine

Discover seamless PVC pipe socketing technology with our line of machines.

PVC Slotting

Discover our highly efficient PVC pipe slotting machine today.

Cooling Tank

SMT cooling tank and vacuum tank for PE,PVC and PPR pipelines.

Haul Off

Pipe pulling machine aka haul off for LDPE, HDPE and PVC pipelines

PVC Cutter

HDPE, PVC, PE and Irrigation pipe cuttersmade in India by – SMT

Die Head

SMT pipe making machine manufacturer present top quality Diehead for best extrusion line.