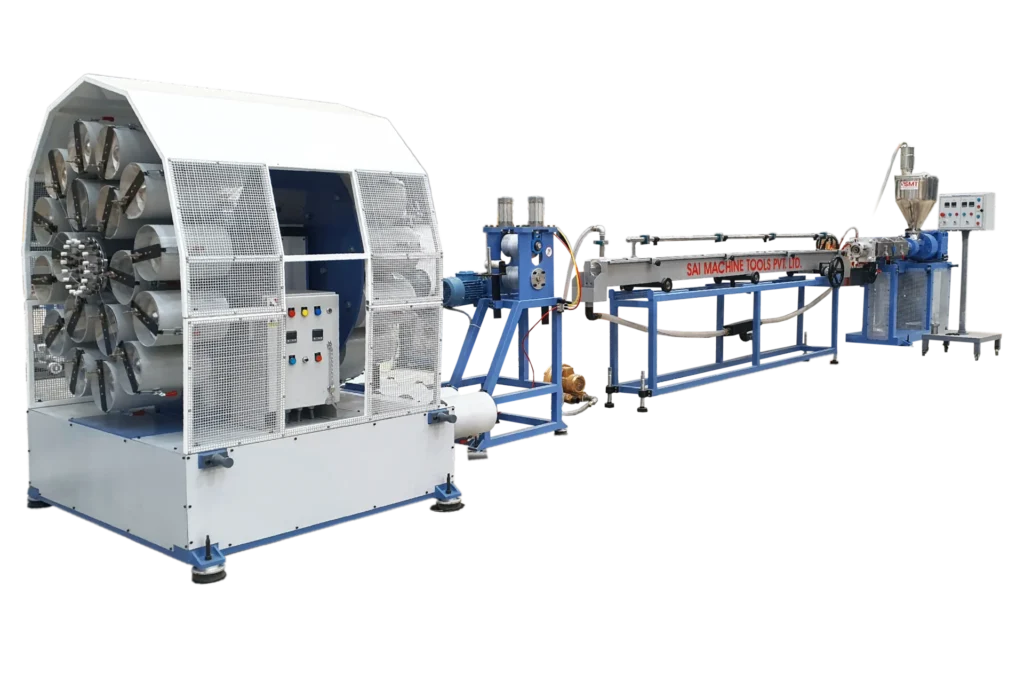

Soft PVC Braided Hose Pipe Extrusion System

Strive for perfection with the top-of-the-line SMT's braided hosepipe-making machine

Sai Machine Tools Pvt. Ltd. presents a top-of-the-line Soft PVC Nylon Braided Hose Pipe Making Machine.

Our SMT Single Screw Extruders are specially designed for producing high-quality soft PVC braided hose pipes. The complete production line includes two extruders, a die head, MS/SS cooling water tank, haul-off unit, high-speed mixer, coiler machine, and other essential equipment.

This machine offers a pipe processing range of 12 mm to 250 mm (½” to 10”) with a production capacity of up to 160 kg/hr. Equipped with a specially designed screw and die head, inverter-controlled AC motor, and top-brand electrical control units, the entire line delivers stable performance and excellent product quality.

Soft PVC braided hose pipes produced on this line are widely used for chemical and gas supply, pneumatic systems, and various industrial applications.

Advanced Soft Braided Pipe Extrusion—Powered by Precision

Our equipment is made from the best-quality materials, ensuring smooth processes and top-notch product output. Our Soft Braided Pipe Extrusion Machine is more than just a production unit — it is a reflection of our commitment to innovation, sustainability, and excellence.

With our advanced soft braided pipe extrusion system, we are fully equipped to meet customer needs better than anyone else.

SMT Nylon Braided Hosepipe

Making Machine Specification

High

Production Speed

Optimal

Energy Consumption

High Grade

Of Automation

High

Production Speed

SMT Nylon Braided Hose Pipe Making machine : For The Best Quality

MODEL | Screw Dia (MM) | Motor (KW) | Max. Output (Kg/Hr.) | Pipe Range (Inch) |

SMT-50X65 SPBH | 50X65 | 7.5+11 | 40 | 1/2" to 2" |

SMT-65X65 SPBH | 65X65 | 11+11 | 80 | 1/2" to 2" |

SMT-65X75 SPBH | 65X75 | 11+15 | 95 | 1" to 3" |

SMT-75X75 SPBH | 75X75 | 15+15 | 120 | 2" to 8" |

SMT-75X90 SPBH | 75X90 | 15+22 | 160 | 3" to 10" |

Why choose Sai Machine Tools Braided Hose Pipe extrusion machine

- Why choose Sai Machine Tools for your braided hose pipe manufacturing?

We are creating premier braided hose extrusion systems with production rates as high as 160kg/hr. Our twin-extruder technology provides the production of braided hoses for chemical and pneumatic applications with durability and reliability. - What braided hoses can your machines manufacture?

We have braided hose production systems that make reinforced braided hoses in diameters from ½” to 10″, for chemical transfer, gas supply, and pneumatic systems. The nylon braid adds superior strength and flexibility. - What are the efficiencies of your braided hose machines?

Our extruder machines utilize optimized screw and inverter drive AC motors for maximum efficiency. This design will provide uniform performance, while improving production energy efficiencies. - What production rates are available on your braided hose machines?

Our braided hose machines produce products ranging from 40kg/hr to 160kg/hr. There are different screw designs, and sizes to accommodate the various production rates and hoses. - How automated are your braided hose systems?

Our systems are complete and fully automated, with precision controls for extrusion, braiding, and coiling. The single-step construction allows for efficient and streamlined handling of raw material to finished product. - What type of business or industries can your braided hose pipes be found in?

Under normal operating conditions, our hoses are typically used by chemical plants, gas suppliers, and an industrial pneumatic system operator. Our hoses are applicable in high-pressure fluid transfer systems. - What safety precautions are built into your extrusion systems?

In addition to standard emergency stopping devices, we have operations temperature precautions. In addition, there is little to be concerned about on the safety front: the extrusion machine’s attributes and strong construction would ensure safe operation even when producing continuously. - Can you supply hoses that have a customized diameter?

Yes. We manufacture braided hoses from ½” to 10″ in diameter, and we can supply hoses in any size that meet the requirements of pressure and flow that may be appropriate. - How energy efficient the hose production machines?

Our hose production systems have been engineered to make optimal use of energy while expending as little as possible, with efficient motor designs and process controls to ensure power use is reduced but productivity and output quality remain very high. - What post-sales support can be expected?

The equipment supplier will provide complete installation instruction and operative training and provide technical support, to ensure you maximize your production requirements. - What materials will your machines work with?

Our extruders only handle of soft PVC formulations; our systems braids nylon (or other) reinforcement into the hoses while utilizing soft PVC. The system can handle a range of formulations, there are developable options to suit different applications. - What gives your braided hoses added durability?

The nylon braid reinforcement offers incredible burst strength. Our hoses provide flexibility and ways to prevent kinking and abrasion. - How user-friendly are your production systems?

Our machines have automated processes that only require minimal manual operations, simple controls for ease of use, and a simple operation procedure. - What maintenance is required for your braided hose machines?

Our systems have been designed using the best grade components meaning they require only simple maintenance. Regular lubrication, cleaning and maintenance will ensure years or reliable service. - Why should you trust Sai Machine Tools to allow you to produce your hoses?

With decades of experience in the extrusion industry we provide innovative solutions using German technology and Indian manufacturing strength. Our machines are trusted around the world to manufacture quality braided hose.