PPR Pipe

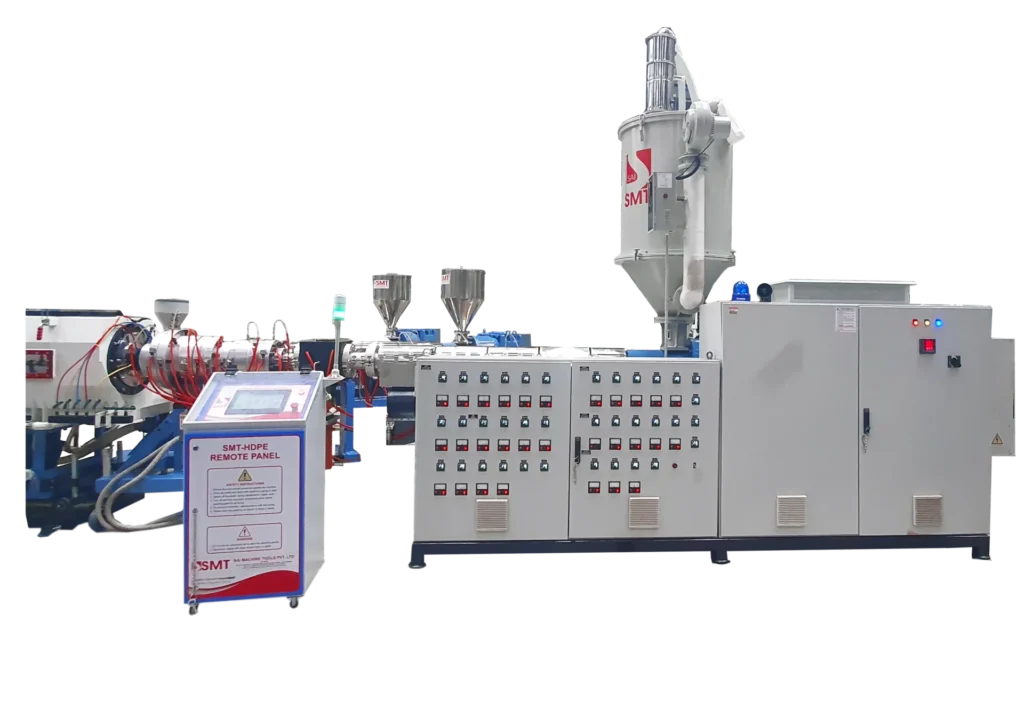

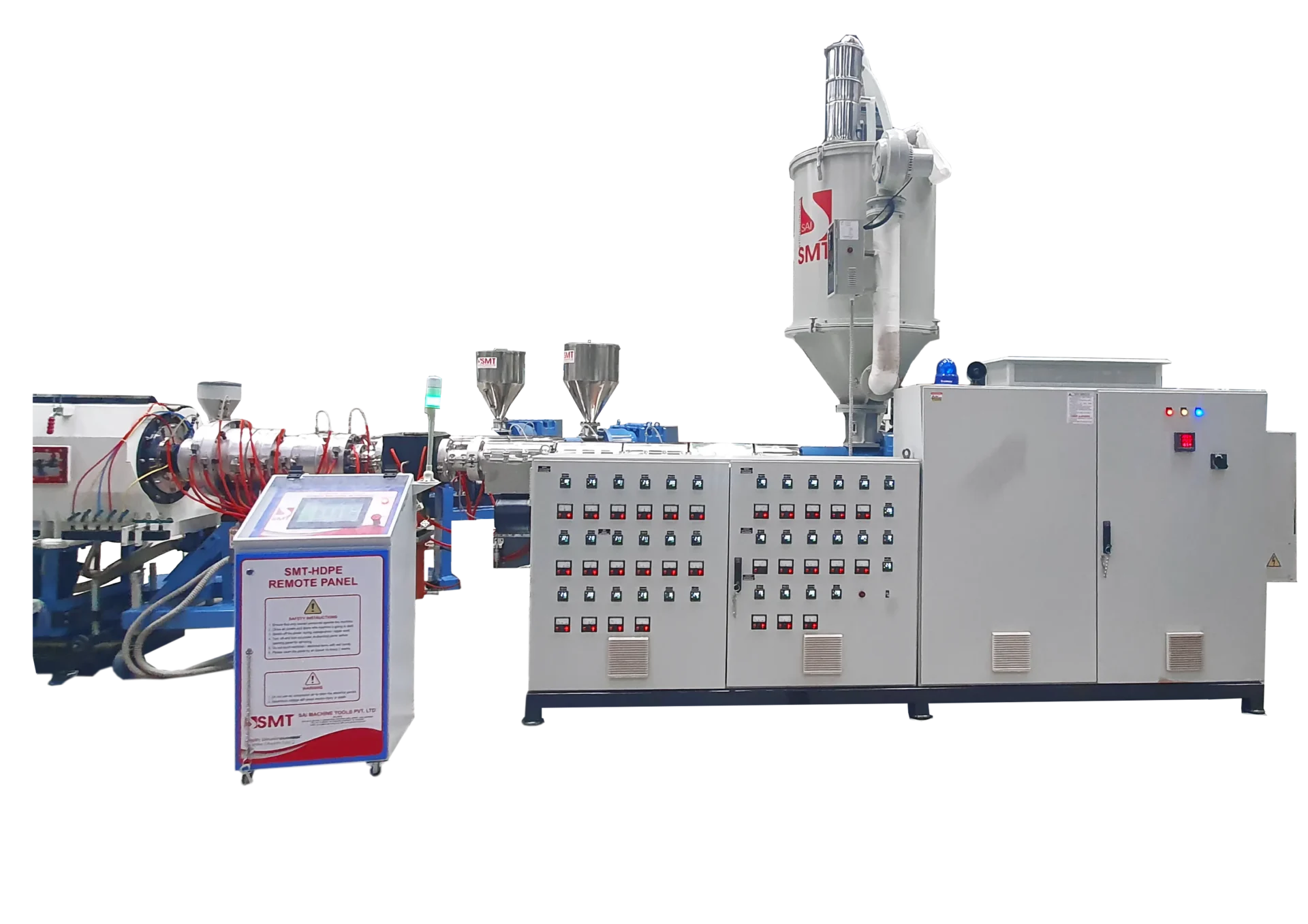

Extrusion Machine

PPR pipe Extrusion line manufacturer Sai machine tools

Sai Machine Tools presents India’s most advanced PPR pipe extrusion system, the machine is based on an indigenous design which increases production capacity with great quality of finished product. It is to this credence that we are proud to announce that this machine has the highest installations of any PPR machine in India till date.

Our PPR cold and hot water pipe production line consists of 3 Extruders, Die Head, Molds, Vacuum Calibrating cooling water tank, Spray cooling water tank, haul-off, printer, cutter, stacker, etc.

With specially designed screw and die head, inverter-controlled AC motor, top brand electrical control units, the whole production line is stable in performance, precise in sizing and excellent in quality.

The machines boast of a wide range of high-capacity main extruders, featuring screw diameters of 65mm, 75mm and 90mm, along with coating extruders of 45mm and 65mm. Pipe production speed of the machine goes up to 15m/min.

At Sai Machine Tools, we also offer complete sets of tooling for various pipe classes, including PN (Pressure Nominal) and SDR (Standard Dimension Ratio), meeting the industry requirements.

You Deserve the Best — And We Deliver It

Our pipe extrusion plants are built using the highest-grade materials to ensure smooth processing and consistently superior product quality. The PPR production plant is more than just a manufacturing setup — it reflects our dedication to innovation, sustainability, and engineering excellence. With our advanced multilayer PPR extrusion system, we are uniquely equipped to deliver unmatched performance and meet the evolving needs of our customers.

PPR Machine Highlights

Main Extruder screw diameter

65mm, 75mm, 90mm and 120mm

Coating extruder screw diameter

45 mm, and 65 mm

Pipe range

16mm to 1200mm

Output capacity

150kg/hr-600kg/hr. (max.)

A Feature-Packed

Powerhouse for Efficiency and Quality

- We give you machines that produce pipes with outer layers that are completely UV resistant and inner layers which are completely anti-microbial.

- Our machines are capable of making pipes with ISI/BIS/DIN Standard.

- As a multi-functional production line, it can also produce HDPE, PP, PEX pipes

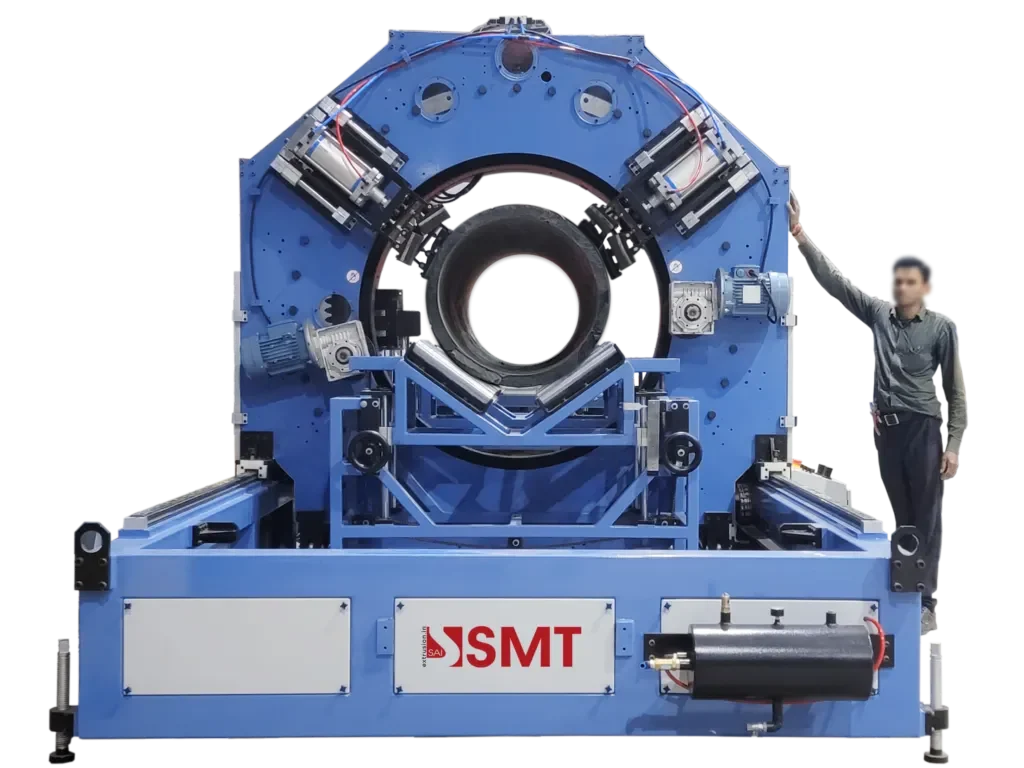

LARGE-DIA-CUTTER

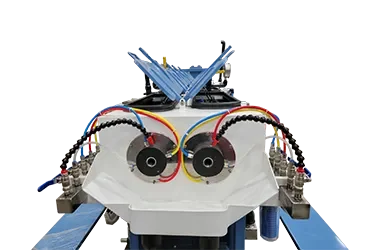

Twin Line Tank

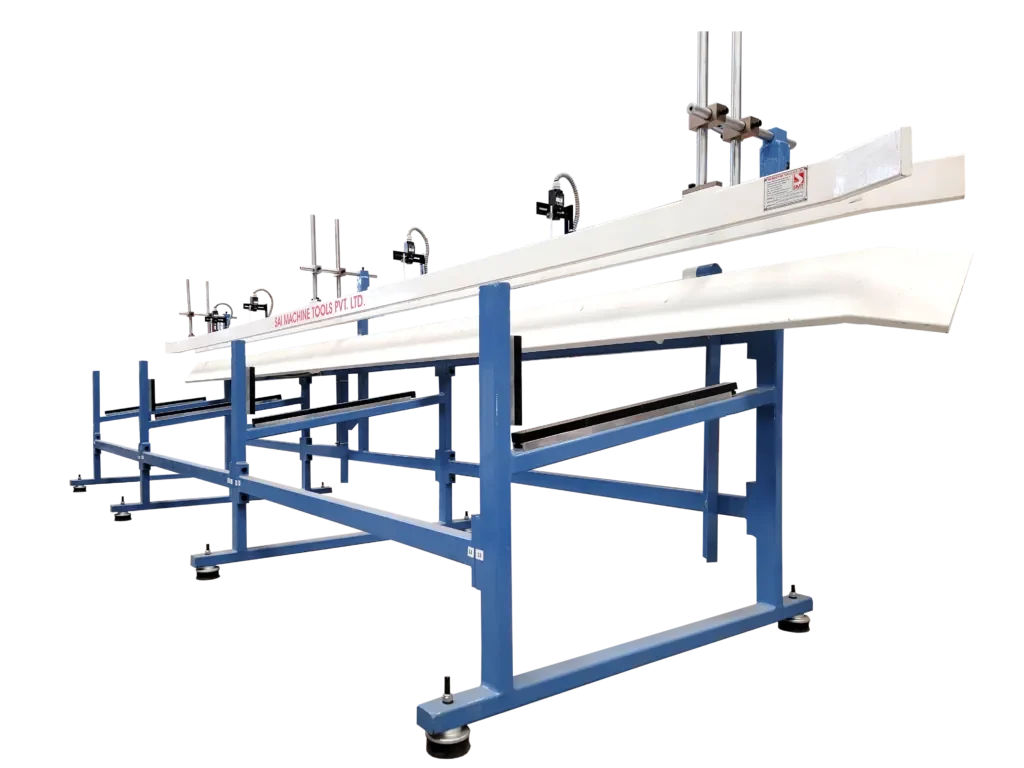

HDPE Tip Table

A Deep Dive into The Specifications of Sai Machine Tools' PPR Pipe-Making Machine

MODEL | Layer | Screw Dia (MM) | L:D Ratio | Main Motor (KW) | Max. Output (Kg/Hr.) | Pipe Range (MM) |

SMT-65X45X45X30-PPR-110 | THREE LAYER ABC TYPE | 65+45+45 | 33:1 | 37+7.5+11 | 150 | 16-110 |

SMT-75X45X45X30-PPR-110 | THREE LAYER ABC TYPE | 75+45+45 | 33:1 | 75+11+15 | 300 | 20-110 |

SMT-75X45X45X30-PPR-200 | THREE LAYER ABC TYPE | 75+45+45 | 33:1 | 75+11+15 | 300 | 20-200 |

SMT-75X65X65X30-PPR-200 | THREE LAYER ABC TYPE | 75+65+65 | 33:1 | 110+45+45 | 550 | 20-200 |

SMT-90X45X45X30-PPR-200 | THREE LAYER ABC TYPE | 90+45+45 | 33:1 | 160+15+18 | 550 | 20-200 |

Note: Aforesaid Machine Models may vary due to customised requirement and continuous R&D.

PPR Extruder

Explore the efficiency of our HDPE pipe extrusion machine

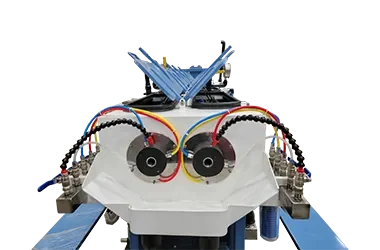

Die Head

SMT pipe making machine manufacturer present top quality Diehead for best extrusion line.

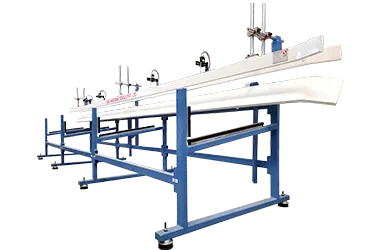

Twin Line Vacuum Tank

SMT cooling tank and vacuum tank for PE,PVC and PPR pipelines. Order Now!

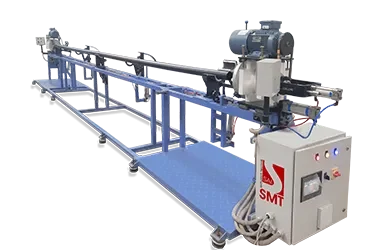

Haul off

Haul Offs (Pipe pulling machine) for LDPE, HDPE and PVC pipelines.

HDPE Cutter

HDPE, PVC, PE and Irrigation pipe cuttersmade in India by – SMT

Tip Table

SMT presents you with reliable tip tables for pipe plants for managing pipe extruding process

HDPE Coiler

With our modern automatic coiler for HDPE pipes, discover productivity. Streamline your business processes.

Friction Welding Machine

Discover the easiest way to operate HDPE pipe friction welding machines.

Why choose

Sai Machine Tools PPR Pipe extrusion machine

Why Sai Machine Tools for PPR pipe production?

We make the most technically advanced PPR pipe extrusion systems in India, and we have more installations for PPR pipe systems than all competing systems combined. Our indigenous design produces a better quality pipe, all at maximum production speeds up to 15m/min.

What types of PPR pipe can your machines produce?

Our systems produce high quality PPR pipes for hot and cold potable water applications, sizes ranging from 16mm to 1200mm diameter. Our machines also manufacture HDPE, PP and PEX pipes.

Why are your PPR pipes more durable?

Our pipes are three-layer, ABC-type pipes with outer layers that resistant to UV radiation, and inner layers that resistant to microbial growth. This 3-layer construction guarantees long-lasting performance in all plumbing applications.

How energy efficient are your PPR pipe machines?

Our extruders use inverter controlled AC motors and offer optimization options for screw design in their high output range and plastic conversion efficiency that minimizes power consumption.

What production capacities do your machines provide?

We can provide machines with outputs from 150kg/hr to 600kg/hr. We have multiple options for screw configurations to allow 65mm, 75mm, 80mm, 90mm, and 120mm designs.

Are your PPR pipes produced to standards quality?

Yes, our pipes conform to ISI, BIS, and DIN standards. The manner of production provides a surety of quality in every run, supporting all international plumbing standards.

How automated is your PPR pipe production line?

Our production line is fully automated, including PLC controls, vacuum calibration, and automatic cutting. The single-line system ensures quality control from extrusion through stacking.

What is your after-sales service support?

Our service includes complete installation support, operator training, and technical support. Our service provides every customer with the assurance that their trigger will guarantee smooth running of the machine for its entire service life.

Can your machines produce multi-layer PPR pipes?

Yes, we produce multi-layer pipes using our ABC-type three-layer extrusion that provides a superior quality pipe. The system ensures that each layer can be controlled very precisely for optimum pipe quality.

What gives your pipe size a much more accurate size?

Our pipes’ sizing is ensured from our vacuum calibration system that can maintain the pipe dimensions very accurately, using controlled cooling to maintain wall thickness as the product traverses through the entire production process.

How easy are your extrusion machines to use?

How much maintenance do your PPR machines need?

Can your machines use recycled materials?

Why are your PPR pipes better for hot water?

Why should I trust Sai Machine Tools to produce PPR?

Experience The Work Of Art

Our Precious Costumers